Why switch from just-in-time to just-in-case with digital transformation?

Just-in-time is being replaced by just-in-case, as reported by numerous newspapers and magazines in recent days.

In the last two years, various events have led to European companies and above all German companies slowly beginning to rethink their purchasing strategies. Exogenous and endogenous factors threaten supply chains and thus indirectly Europe as a production location in general and Germany as a production location in particular. Examples are:

- Unpredictable pandemics and courses of infection, such as the corona and the monkeypox infections that are just burgeoning

- Massive internal political changes in some European countries with new goals and new doctrines

- Raid wars

- A new political polarization between the US and Russia and the US and China

- Accidents on established trade routes, such as the Suez Canal blockade

- “Privatization” of new trade routes, such as the New Silk Road

- Unnoticed political changes in Africa and South America

- Unnoticed political changes in China, the so-called workbench of the world

- Lack of expertise on China’s political, geopolitical and economic realignment in governments and companies

What if supply chains continue to collapse?

“Greed is cool!” and “cheap, cheap, cheap” are still doctrines in many economic sectors, but above all in public administration and especially in the minds of many private consumers, who often take their attitude into their professional reality take along.

This attitude of the people and the governments, which had no talent for the development of China and currently do not have, as well as many other small factors, have led to European companies investing in China’s economic future and moving production from Europe to China. Not only were expensive workers cut off in Europe, but above all there was an exodus of technical knowledge and patents.

The supply chains are partially collapsing

Because, despite all the warnings from experts, a particularly large number of productions were relocated from Europe to China, secure supply chains had to be set up that guaranteed cost-effective just-in-time production in Europe for the actual end products.

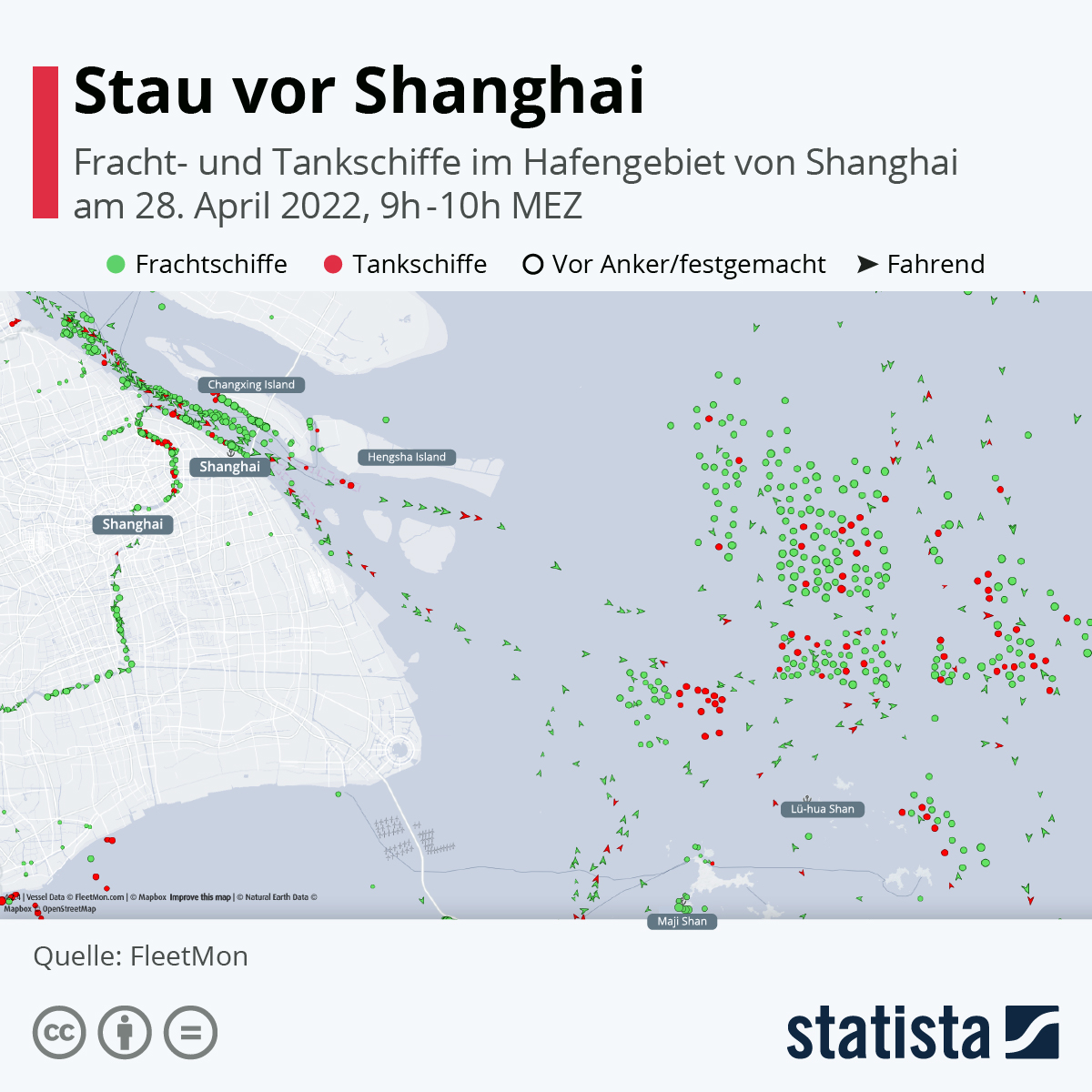

However, the aforementioned nine factors are putting these supply chains at risk and in many cases even disrupting or completely collapsing, as is currently being seen in Shanghai.

“Industry President Siegfried Russwurm told the German Press Agency in Berlin: ‘German industry fears disrupted production processes in the coming weeks. The sectors that are particularly affected are those that depend on the delivery of raw materials or components and the shipping of their finished products by sea transport.'” Internet portal Statista on April 28, 2022 with reference to the ships that are currently off Shanghai and are not being handled.

Just-in-case - immediate measures at the scene of the accident

In the opinion of my wife, Renate Sattler, former chairwoman of the Chamber of Commerce for South and Southwest China in Guangzhou, China, and many experts, the European economy must switch from just-in-time processes to just-in-case processes . Just-in-time can be part of just-in-case.

According to the website Theidioms.com, just-in-case means “to do something as a precaution” or “to engage in something intended as an alternative in case the original doesn’t work”.

In concrete terms, this means that countermeasures must be taken in the event of a supply chain interruption. This could be:

- Stockpiling of raw materials and semi-finished products – A few years ago, VW had missing glove compartment flaps for the Passat because a factory for glove flaps had burned down.

- Development of parallel productions for products from China in Europe and then reducing the dependence of the European economy on China.

- Acceptance of higher production costs and thus price increases for the end products. – The production of FFP2 masks was ramped up in Europe, only to be bought back in China for cost reasons.

If European companies switched their production from just-in-time to just-in-case, this means new risks, new strategies, new production methods, new procurement of raw materials and much more, even if China already controls large parts of the raw materials market in Africa and South America.

Mechanisms and solutions from digital transformation can help to minimize the risks of this changeover.

How can digital transformation help?

If we take data from the previous productions of a company, the most brilliant thing would be data from all companies in an industry from their previous productions, then with the mechanisms of statistics and stochastics (probability calculation) as well as big data methods, detailed forecasts for reducing risk and for Increase in availability possible.

A shutdown, as forecast by Industry President Siegfried Russwurm, could almost be ruled out and the European economy would be much more robustly armed against disruptions of any kind.

Author

Claus Michael Sattler is a consultant and interim manager, book author and keynote speaker as well as university lecturer for “Digitization, Digital Transformation, Industry 4.0, Reference Architecture Model Industry 4.0 (RAMI 4.0), Industrial Internet of Things (IIoT) and Made in China 2025”. He lectured and continues to teach at the International Graduate Center (IGC) of the Bremen City University of Applied Science (HSB), at the International Institute for Management Development (IMD), Lausanne, Switzerland, at the WHU – Otto Beisheim School of Management in Vallendar Koblenz, Germany.

Contact Details

Formal / Legal

Claus Michael Sattler

(Master Craftsman / Business Economist)

P.O.-Box 1142

28833 Weyhe

Germany

Telephone: 0049 (174) 6031377

Email: cmsattler@cmsattler.de

This website is not a commercial site, but my personal business card.

China-Consulting-Partner

Contact Details

Telefon: 0049 (151) 28841087

E-Mail: rs@china-consulting-partner.com

Internet: https://www.china-consulting-partner.com

Contact Details

Telephone: 0049 (151) 28841087

email: rs@china-consulting-partner.com

internet: https://www.china-consulting-partner.com

In order to facilitate the flow of reading, we generally restrict ourselves to male designations in the course of the text. We expressly emphasize that all people – regardless of gender, nationality, ethnic and social origin, religion/belief, limitations, age and sexual orientation – are equally welcome here.